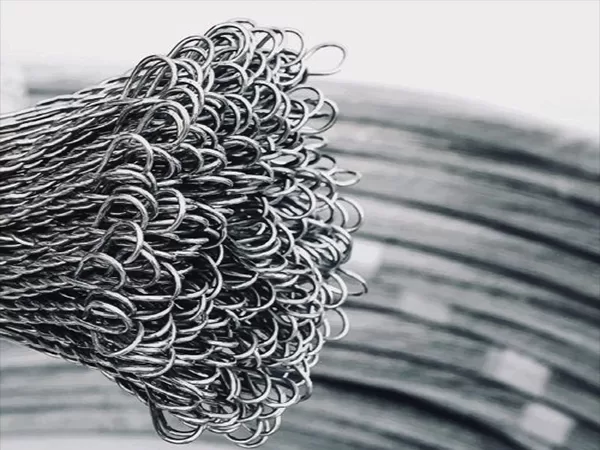

Galvanized Hi-Tensile Baling Wire

Galvanized Hi-Tensile Baling Wire at Wire Industries LLC

Galvanized Steel Wire Defined

Galvanized steel wire stands as a representation of steel wire coated in zinc to shield it from the ravages of corrosion, a process known as galvanization.

This galvanization technique encompasses the deposition of a protective zinc layer onto the steel wire. This acts as a fortress, barring oxygen and water – the primary culprits of steel degradation and rust.

With a vast array of applications spanning from construction to agriculture, galvanized steel wire also finds use as an electrical conduit, given its enhanced resistance to corrosion compared to its counterparts. This invaluable material plays a pivotal role in extending the lifespan of steel commodities and offering them a shield against environmental challenges.

Diverse Uses of Galvanized Steel Wire

Galvanized wires boast of a multitude of applications, some of which include:

• Boundary Solutions: Employed in crafting fences and gates, the anti-rust properties of the zinc coating make galvanized wire an exemplary candidate for exterior setups.

• Overhead Supports: From curtain rods to clotheslines, the robust and lasting character of galvanized wire makes it a prime choice for bearing weighty objects.

• Window Security: Be it in residences, commercial spaces, or retail outlets, galvanized wire can be twisted around window frames, anchored in place using nails or fixtures.

• Binding & Packaging: Whether it’s bundling, fastening, or baling, the resilience of galvanized wire ropes and tie wires shines through, making them preferred tools for such tasks.

• Eco-consciousness: A nod to sustainability, galvanized wires can transition into novel steel commodities, curbing environmental harm and preserving nature’s reserves.

• Confinement: With its knack for ensuring firmness, it’s no wonder that galvanized wire emerges as a top choice in packaging solutions.

Moreover, the construction and industrial sectors frequently utilize galvanized wire mesh for purposes like fencing, bolstering, or serving as a safeguard.

Advantages of Opting for Galvanized Steel Wire

Several merits accompany high-tensile galvanized wires:

• Their impressive tensile strength earmarks them for a plethora of functions, spanning construction, agriculture, and myriad industrial realms.

• They tower above others with their unparalleled resistance to corrosion.

• Given their diminished susceptibility to rust, they excel as candidates for electrical pathways.

• Customizability is key – with galvanized wires available in diverse gauges to cater to bespoke requirements.

• Embracing eco-responsibility, these wires can be reborn as new steel entities, championing environmental well-being and judicious use of resources.

Galvanized Wires at Wire Industries LLC.

Hi-Tensile 10 Gauge Galvanized Tie Wire

Distinguished by its robustness, our 10-gauge high-tensile galvanized wire is a paragon in Wire Industries LLC’s line-up. With a decimal diameter between 0.119 – 0.121 inches, it offers an outstanding tensile strength that ranges from 145,000 to 175,000 PSI. The wire’s elongation metric stands between 7-11%, and its high carbon composition, rated as 1065, bolsters its fundamental strength. Augmented with a galvanized coat, this wire effectively counters corrosion, making it indispensable in environments with corrosive elements.

Hi-Tensile 11 Gauge Galvanized Bale Tie Wire

Our Hi-Tensile 11 Gauge wire is tailored for versatility across multiple applications. It boasts a diameter of 0.121 inches and a coil break range spanning from 1781 to 2011. This wire’s tensile strength, ranging between 145,000 to 175,000 psi, makes it an ideal choice for high-demand tasks. Thanks to its galvanized layer, the wire demonstrates exemplary corrosion resistance, marking it suitable for conditions prone to rust.

Hi-Tensile 12 Gauge Galvanized Wire

Wire Industries LLC’s 12-gauge high-tensile wire, available in 12 GA specification, melds durability with consistency. It registers a coil break range between 1341 to 1515 and maintains a tensile strength ranging from 145,000 to 175,000 psi. These attributes designate it as one of the robust wires in our roster.

High-Tensile 14 Gauge Galvanized Baling Wire

Precision-crafted, our 14-gauge high-tensile galvanized wire exemplifies durability and strength. It possesses a decimal diameter of 0.078 – 0.080 inches and delivers a load capacity that varies from 698 to 898 lbs. This wire showcases a tensile strength of 170,000 PSI and has an elongation rate set between 7-11%. Its high carbon composition, denoted as 1045, further solidifies its reputation. The protective galvanized layer ensures it remains resistant to corrosion, rendering it ideal for a plethora of applications.

Post-refinement, the wire is immersed in a hot-dip galvanizing bath. This zinc armor not just wards off corrosion, but also potential damages, ensuring the wire’s longevity. It’s then beautified with a finish that merges protection with aesthetic elegance.

In a domain where some might cut corners, Wire Industries LLC reaffirms its commitment to unmatched quality. Every batch of our vineyard grade wire is tested rigorously, ensuring consistency.

How to Order Your Tie Wire

Get a quick quote in less than 30 minutes during regular business hours by completing our contact form. Just provide your wire specifics and contact information, and we’ll get back to you promptly.

For more information about our 11-gauge galvanized high-tensile bale tie wire offerings and their prices, get in touch with Wire Industries LLC at (770) 507-5700. Our team of experts is available to offer insights and guide you to the right gauge of black annealed box wire suited to your baling equipment and to fit your needs.

We Stay Stocked To Better Serve You

More Wire Industry Focused Products

Automatic Baler Wire - Coils

Black Annealed or Galvanized in 100lb or 50lb coils. Available in 10, 11 and 12 gauge.

Black Annealed or Galvanized. 125 or 250 pieces per bundle. Coiled and palletized, boxed on pallet, or straight lengths. 10, 11, 12, 13, and 14 gauge. Length up to 22′.

Automatic Baler Wire - Carriers

Black Annealed or Galvanized Hi Tensile Strength 1500lbs – 2000lbs / Carrier

We provide parts and service for all wire tie machines

Galvanized or Bright Spring Quality. 10, 10.5, 11, 11.5, 12, 12.5, 13, 13.5 and 14 gauge. Length up to 21′ (Specify Length) Packaged in 100, 125, 150 and 250 pieces/bundle.

Steel Strapping and Accessories

Regular Duty and Hi Tensile Steel. Oscillated or Millwound Coils. Pneumatic or Hand Tools and Tool Repair Dispensers and Seals.

Stitching Wire

Galvanized or copper-coated in 25lb or 50lb coils.

Plastic and Nylon Strapping

Polyester or polypropylene. Hand and machine grade. Manual, automatic and semiautomatic equipment. Tools, dispensers, seals and all accessories including tool repair.

Stretch Film

Hand grade from 4″ to 20″. Machine grade in all sizes. Complete machine line and accessories.